Publications

Ice Shedding Trajectory Analysis and Impact Measurement on a Large-Scale Propeller Test Rig

Johannes Burger, Alexander Scheicher and Manuel Gerstenbrand

AIAA AVIATION FORUM 2025, DOI: https://doi.org/10.2514/6.2025-3299

Abstract

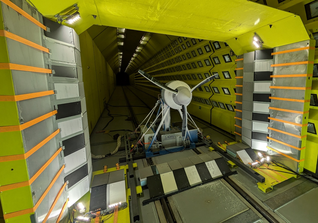

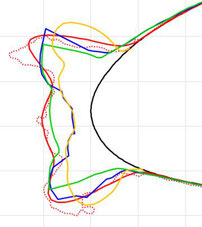

Advanced methodologies are presented for analyzing ice shedding events from large-scale propellers during icing tests in a climatic wind tunnel. Significant improvements were made to the three-dimensional reconstruction of ice shedding trajectories, including enhancements to the camera system, calibration procedure, particle tracking, and correspondence algorithms. A novel particle capture system was developed and integrated into the wind tunnel, enabling the collection and preservation of ice shedding particles for measurement. By correlating the mass of collected particles with their impact velocities, the kinetic energy at the moment of impact was determined. Microtomography provided detailed assessments of particle shape, volume, and ice density. These techniques were applied in two test campaigns involving large-scale propellers equipped with electrothermal ice protection systems at the Rail Tec Arsenal Icing Wind Tunnel. The resulting data offer new insights into the dynamics of propeller ice shedding and support improved modeling and design of ice protection systems.

Experimental Investigation of a Quadcopter UAS with a Fluid-Based De-Icing System in Appendix C Icing Conditions

David Kozomara, Jakob Amon, Reinhard Puffing, Richard Moser, Wolfgang Breitfuss, Thomas Neubauer,

Simon Schweighart, Ingeborg Bednar and Stephan Thein

AIAA AVIATION FORUM 2024, DOI: https://doi.org/10.2514/6.2024-4072

Abstract

In-flight icing is a major challenge for the safe operation of unmanned aerial systems (UAS). Research results indicate that a short icing exposure of few minutes can have critical effects for the continuation of a flight mission if no measures are taken. Depending on the severity of the encountered icing conditions and the duration of exposure, icing on an unprotected UAS can lead to a performance degradation or in a worst-case scenario to a loss of the aircraft. This paper presents results from an experimental investigation in icing conditions with a quadcopter in the category of small UAS with 25 kg, respectively 55 lbs, of maximum take-off weight. The investigation was performed at the icing wind tunnel of Rail Tec Arsenal in Vienna, Austria. The quadcopter was mounted on a newly developed testbed for small UAS and exposed to Appendix C icing conditions. During the icing encounter, the main performance parameters (thrust, rotational speed and power consumption) were logged. The final ice accretion was documented by means of 3D laser scanning and photographs. In addition to unprotected reference cases, the application of a novel low energy fluid-based de-icing system was tested. The research was conducted as part of the FFG/BMK funded project “All-weather Drone”.

Development of a Test Rig for Investigating Propeller and Rotor Icing

Jakob Amon, Manuel Gerstenbrand, David Kozomara, Wolfgang Hassler, Reinhard Puffing and Simon

Schweighart

AIAA AVIATION FORUM 2024, DOI: https://doi.org/10.2514/6.2024-4113

Abstract

The use of unmanned aircraft systems (UAS) across different applications is growing. With this increase in demand, the capability to be able to operate the UAS in “all-weather conditions” is seen as an essential requirement for future UAS. Research results indicate that in-flight icing is especially relevant and can have a large impact on the overall performance of the UAS and the safety of operation. Therefore, to meet these requirements, the drone industry and the field of icing research is increasingly focusing on the topic of UAS in-flight icing. One issue is that experimental testing possibilities under defined icing conditions for the specific needs of UAS are only available to a limited extent and are often associated with high costs. This paper presents a mobile test facility, which can be deployed in a climate chamber and uses gravity instead of an air flow to create the required icing conditions. The approach differs from conventional icing wind tunnel setups and testing. The developed test rig enables a flexible and cost-efficient investigation of the effects of icing on propellers, rotors and possibly entire drones under CS-25 Appendix C icing conditions. This paper details the construction, functionality, and calibration of the test rig so far along with the challenges encountered and insights gained throughout the process.

Characterization of Propeller Icing from 3D Laser Scan Data

Thomas Neubauer and Ezgi S. Oztekin

AIAA AVIATION FORUM 2024, DOI: https://doi.org/10.2514/6.2024-4350

Abstract

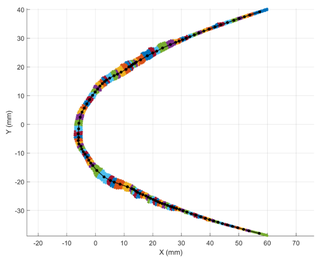

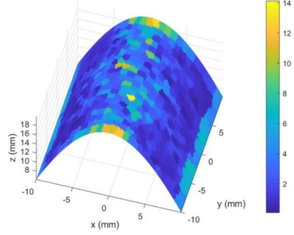

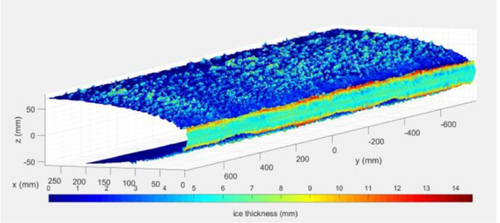

In this study, a new method is proposed to characterize propeller ice shapes based on 3D laser scanning. The

demonstrated approach allows for the calculation of common ice shape characteristics, such as the mean ice shape or the Maximum Combined Cross Section (MCCS) on highly three-dimensional profiles,

such as a propeller. The approach can be generalized for any three-dimensional geometry with twist, taper, and sweep. For the investigation presented here, the twist of the propeller geometry is

normalized to allow a comparison of cross sections of ice shapes in spanwise direction. Additionally, this method allows for the consideration of multiple blades, allowing the calculation of a

single mean ice shape or MCCS. In this study, the described method is illustrated and applied to 3D scans obtained during icing wind tunnel tests performed at Rail Tec Arsenal in Vienna in 2023.

The experimental icing tests were performed on a three-blade variable pitch propeller with 2.36 m diameter in Appendix C conditions. The results demonstrate a practical and deterministic

approach, providing a means to characterize the intricate three-dimensional nature of icing using simple characteristic curves on lower-dimensional manifolds. This method offers a practical way

to compare experimental cases with each other or with the outcomes of numerical icing simulations. Moreover, it can be shown that the applicability of the presented method extends beyond rotating

components, making it suitable for a wide range of non-rotating elements such as 3D wings.

3D Reconstruction of Ice Shedding Trajectories on a Full-Scale Propeller Test Rig

Johannes Burger, Alexander Scheicher, Victoria Fill, Florian Knöbl and Thomas

Neubauer

AIAA AVIATION FORUM 2024, DOI: https://doi.org/10.2514/6.2024-4351

Abstract

A new method was developed to document and reconstruct ice shedding events from a full-scale propeller tested

in a climatic wind tunnel. A stereo system of synchronized high-speed cameras was used to capture footage of the ice shedding from two different perspectives. Motion-based multiple object

tracking was applied to automatically locate ice particles in the series of images. Stereo triangulation was performed on corresponding particle tracks to determine the three-dimensional position

of the respective ice particles in each frame. This approach makes it possible to reconstruct the three-dimensional trajectories of shed ice particles, giving detailed insight into their location

of detachment and impact. A regression model was computed to approximate the particle trajectory and to derive the particle velocity. The workflow was demonstrated on icing tests of a full-scale

general aviation propeller operated in the Rail Tec Arsenal icing wind tunnel. Data of shedding events recorded during these tests is presented, discussed, and evaluated for improvements of the

documentation method.

IMPACT: Experimental and numerical ice shapes on swept-wing models with straight and undulated leading edges

Isik A. Ozcer, Guillaume Moula, James Page, Alessandro Zanon, Michele De Gennaro, Thomas Neubauer, Simon

Schweighart and Raul C. Llamas-SandinThomas

AIAA AVIATION FORUM 2024, DOI: https://doi.org/10.2514/6.2024-4160

Abstract

This paper presents part of the results of the experimental swept wing icing campaign undertaken as part of the

CleanSky 2 IMPACT project (GA no. 885052), along with the numerical simulation results obtained with Ansys FENSAP-ICE and Fluent Icing. One of the goals of this experimental campaign was to

provide high quality ice shape validation data for 3D icing simulation codes on undulated leading edges, which are of interest due to their potential tolerance to aerodynamic performance

degradation due to ice. Using the NACA 3421 airfoil profile as baseline, an undulated leading-edge geometry was designed and tested in addition to the original straight leading edge, to study the

differences in ice shape formations on both geometries. The experiments were carried out at the Rail Tec Arsenal (RTA) facility in Vienna (Austria). The wing model had a sweep of 20º and a chord

length of 1.5m. The icing conditions included air speeds from 60 to 70m/s, static temperatures from -20° to -1.4° C, LWCs from 0.21 to 0.64 g/m3, and MVDs from 20 to 101.4 microns. Icing times

were set to 15 minutes, with two runs extended to 45 minutes. The experimental data collected include 3D ice scans and 2D ice tracings extracted from these scans, ice thickness distributions, ice

density measurements, and aerodynamic forces. The numerical simulations are done using the multi-shot method in FENSAP-ICE, which updates the CFD mesh regularly to account for the two-way

coupling of surface deformation and air flow. Simulation model settings studied include mesh resolution, icing time between mesh updates, and ice density options.

Novel Passive Icephobic Surfaces – Experimental Investigations in a Small-Scale Icing Wind Tunnel

Roland Fürbacher, Wolfgang Hassler, Hannes Steiner, Thomas Neubauer, Johannes Hufnagl, Ľuboš Bača, David

Kozomara, Sebastian Spalt, Andreas Hinterer and Gerhard Liedl

AIAA AVIATION FORUM 2024, DOI: https://doi.org/10.2514/6.2024-4353

Abstract

Passive icephobic surfaces have the potential to significantly impact aviation especially the field of unmanned

aerial vehicles (UAVs). The intrinsic properties of a surface can be designed to repel super-cooled water droplets to a large extent from accreting to the aircraft surface in form of ice.

Thereby, reducing the need for active de-icing measures and increasing the safety in case of an inadvertent icing encounter. However, current anti-ice coatings are susceptible to erosion and the

anti-ice properties often lack durability. This paper presents a novel approach to create functional and robust passive icephobic surfaces. The performance of the novel coatings is evaluated by

an experimental investigation performed in a small-scale icing wind tunnel (IWT). The novel approach features a state-of-the-art femtosecond laser process to create periodic surface structures

with overlaying coatings. Hydrocarbon post-laser treatment was used to receive superhydrophobic layers and decrease ice adhesion. Additionally, hydrophobic Hexamethyldisiloxane (HMDSO) was tested

via atmospheric plasma spraying on top of laser structures to enhance the anti-ice performance. Furthermore, thin superhydrophobic films of a silicon epoxy hybrid resin with a silane-modified

perfluoro polyether have been applied on laser structures by spray-coating to reduce ice accumulation. Lab results showed a significant decrease in ice adhesion and high static contact angles.

Improved initial water runback and an icing delay were observed during the IWT tests, resulting in a smooth leading edge ice shape compared to the reference surfaces. Computational fluid dynamics

simulations (CFD) have been performed using 3D laser scanned ice shape data from one selected IWT test to estimate the effect of the different ice shape geometry on aerodynamics. The results

indicate an improvement in aerodynamic performance for the laser structured and HMDSO-coated surface.

CFD Simulation of Condensation Processes of Humid Air in Aircraft Liquid Hydrogen Fuel System Boil-Off Lines

Andreas Tramposch, Maximilian Angermayr, Philip Kirschnek and Johannes Burger

AIAA AVIATION FORUM 2024, DOI: https://doi.org/10.2514/6.2024-4034

Abstract

The development of efficient and sustainable aircraft engine fuel systems has become one of the primary aspects

in achieving the long-term goal of net-zero CO2 emissions from aviation by 2050. Using liquid hydrogen can offer longer endurance for air vehicles and effective engine cooling due to its high

specific heat compared to high-pressure systems. However, due to low temperatures of the liquid hydrogen, water vapor present in ambient humid air can condense on certain aircraft fuel system

components and freeze. The focus of this work is the development of a parameterized CAE worflow to investigate the influence of various input parameters on the local temperatures and the liquid

water content in the boil-off line of an aircraft fuel system with a closed boil-off valve. This paper provides a discussion of different CFD multiphase modeling approaches for a multiphase flow

of humid air (mixture of dry air and water-vapor) and liquid water, including the condensation process taking place. In order to validate the simulation results, scaled tests were carried out in

a climate test cabinet with a thermal imaging camera and a micro-CT used to determine the external wall temperatures and the water content in the pipe.

Experimental Investigation of a CRM65 Wingtip Mockup under Appendix C and Appendix O Icing Conditions

Reinhard Puffing, Thomas Neubauer, Richard Moser, Wolfgang Hassler, Simon Schweighart, Hermann Ferschitz,

Stefan Diebald, Wolfgang Breitfuss and David Kozomara

SAE 2023 International Conference on Icing of Aircraft, Engines, and Structures, DOI: https://doi.org/10.4271/2023-01-1386

Abstract

Research institutes and companies are currently working on 3D numerical icing tools for the prediction of ice

shapes on an international level. Due to the highly complex flow situation, the prediction of ice shapes on three-dimensional surfaces represents a challenge. An essential component for the

development and subsequent validation of 3D ice accretion codes are detailed experimental data from ice shapes accreted on relevant geometries, like wings of a passenger aircraft for example. As

part of the Republic of Austria funded research project JOICE, a mockup of a wingtip, based on the National Aeronautics and Space Administration common research model CRM65 was designed and

manufactured. For further detailed investigation of electro-thermal de-icing systems, various heaters and thermocouples were included. The mockup was investigated in the Icing Wind Tunnel of Rail

Tec Arsenal in Vienna, Austria under various Appendix C and Appendix O icing conditions with and without activated heating systems. The resulting ice structures were documented and analyzed by

using 3D and 4D scanning systems. This paper provides information about the design of the mockup, the test setup in the Icing Wind Tunnel well as the applied documentation procedures.

Furthermore, an overview of the conducted experimental investigations is given, and selected results and evaluations are presented.

Experimental Investigation of UAS Rotors and Ice Protection Systems in Appendix C Icing Conditions

David Kozomara, Jakob Amon, Reinhard Puffing, Thomas Neubauer, Simon Schweighart, Stefan Diebald, Andreas

Rapf, Richard Moser and Wolfgang Breitfuss

SAE 2023 International Conference on Icing of Aircraft, Engines, and Structures, DOI: https://doi.org/10.4271/2023-01-1380

Abstract

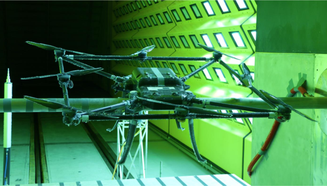

If an Unmanned Aerial System (UAS) encounters icing conditions during flight, those conditions might result in

degraded aerodynamic performance of the overall UAS. If the UAS is not reacting appropriately, safety critical situations can quickly arise. Thereby, the rotors, respectively the propellers of

the UAS are especially susceptible due to the increased airflow through their domain and the corresponding higher impingement rate of supercooled water droplets. In many cases, the UAS cannot be

properly operated if the rotors are not fully functional, as they are a vital component. The FFG/BMK funded research and development project “All-weather Drone” is investigating the icing

phenomenon on UAS rotors for a 25 kg maximum take-off weight (MTOW) multirotor UAS and evaluating the feasibility of possible technical ice detection and anti-/de-icing solutions. This paper

presents results from the investigation carried out at the Rail Tec Arsenal (RTA) icing wind tunnel (IWT) in Vienna, Austria, where UAS rotors were exposed to defined icing conditions based on

EASA CS-25 Appendix C. The experimental tests featured various rotors which were exposed to icing conditions without any protective measures to better understand the influence of ice accretion on

the aerodynamic performance. In addition, possible technical solutions in form of an electrothermal and chemical anti-/de-icing system, as well as an ice-repellent surface coating were

investigated. During the tests, the performance (power, thrust, torque) of the UAS rotors was monitored. The final ice accretion was documented by 3D laser scanning and photographs. The objective

of this work is to contribute to a better understanding of icing of UAS rotors, while also investigating solutions that might enable the safe operation of multirotor UAS in icing conditions in

the future.

Time Resolved 3D Scanning of Ice Geometries in a Large Climatic Wind Tunnel

Thomas Neubauer, David Kozomara, Reinhard Puffing and Luca Teufl

SAE 2023 International Conference on Icing of Aircraft, Engines, and Structures, DOI: https://doi.org/10.4271/2023-01-1414

Abstract

In the scope of development or certification processes for the flight under known icing conditions, aircraft

have to be tested in icing wind tunnels under relevant conditions. The documentation of these tests has to be performed at a high level of detail. The generated data is used to prove the

functionality of the systems, to develop new systems and for scientific purposes, for example the development or validation of numerical tools for ice accretion simulation. One way of documenting

the resulting ice geometry is the application of an optical 3D scanning or reconstruction method. This work investigates and reviews optical methods for three-dimensional reconstructions of

objects and the application of these methods in ice accretion documentation with respect to their potential of time resolved measurement. Laboratory tests are performed for time-of flight

reconstruction of ice geometries and the application of optical photogrammetry with and without multi-light approach. The results of the pre-tests and the review of existing methods are evaluated

with respect to scaling of the methods for application in a large icing wind tunnel. As a result of this process, multi-view photogrammetry is used for 3D reconstruction of ice accretion on a

common research model wing tip installed in the icing wind tunnel of Rail Tec Arsenal. The results are compared with 3D laser scans of the final ice geometry. The presented approach allows a time

resolved quantitative documentation of an icing process without interrupting the experimental ice accretion process.

Comparison of Numerical Simulations with Experimental Data for an Electrothermal Ice Protection System

in Appendix O Conditions

Wolfgang Breitfuß, Richard Moser, Wolfgang Hassler, Hermann Ferschitz, Thomas Neubauer, Reinhard Puffing, Stefan Diebald and Simon Schweighart

SAE 2023 International Conference on Icing of Aircraft, Engines, and Structures, DOI: https://doi.org/10.4271/2023-01-1396

Abstract

This paper provides information on the comparison of numerical simulations with experimental data for an

electrothermal ice protection system with a focus on Appendix O Freezing Drizzle (FZDZ) and Freezing Rain (FZRA) conditions. The experimental data is based on a test campaign with a 2D NACA23012

wing section in the RTA Icing Wind Tunnel in Vienna. 22 icing runs (all either unheated or in anti-ice mode) were performed in total and all residual ice shapes were documented by means of

high-resolution 3D scanning. Unheated FZDZ and FZRA reference as well as heated cases with different heater configurations are presented. The experimental results are compared to numerical

predictions from two different icing codes from AeroTex GmbH (ATX) and the University of Applied Sciences FH JOANNEUM (FHJ) in Graz. The current capabilities of the codes were assessed in detail

and regions for improvement were identified. Overall, the codes were able to predict the ice shapes of both the unheated and heated cases with reasonable accuracy but both codes overestimated the

thickness of the runback ice ridges throughout all cases. The biggest deviations in terms of the position of the ice accretions were seen on the lower surface; on the upper surface a better match

was observed.

Introduction of an Online Ice Accretion Database

Thomas Neubauer and Reinhard Puffing

SAE 2023 International Conference on Icing of Aircraft, Engines, and Structures, DOI: https://doi.org/10.4271/2023-01-1464

Abstract

In the course of the Horizon 2020 project ICE GENESIS of the European Union, an experimental database was

developed to host documentation of icing experiments. The database serves as a source of information for numerical code development and validation as well as future test matrix design, IPS layout

and development and wing design. Several legacy data icing cases have been included into the database, which are partly publicly available. Furthermore, the database will serve as the main

platform for dissemination of public results of icing cases after and during the project ICE GENESIS. The database itself provides detailed information about the test configurations and the icing

wind tunnel. More specifically, CAD data, ice protection system characteristics if applicable, installation in the test facility, instrumentation, test matrix, generated aero-icing conditions and

test results are included. Within the ICE GENESIS project, the documentation of the resulting ice accretion is done by the application of 3D scanning systems, which allows detailed ice shape

evaluation and validation of 3D numerical tools performances. The database covers a large set of representative configurations (2D and 3D wings, engine inlets, cylinders) and will complement

worldwide existing databases.

Engine Cascade Rig Design Tests and Results in App C Conditions

Hugo Pervier, Clément Vénuat and Thomas Neubauer

SAE 2023 International Conference on Icing of Aircraft, Engines, and Structures, DOI: https://doi.org/10.4271/2023-01-1419

Abstract

Current modelling capability for engine icing accretion prediction is still limited for App. C. To further validate icing codes in complex engine geometries, it is necessary to perform additional experimental work in relevant geometrical and environmental conditions. Within the frame of ICE GENESIS, an experiment has been setup to replicate the condition at the inlet of an engine first stage compressor. This paper describes the choices for the design of the engine compressor model, the setup within the icing wind tunnel and the methodology employed to obtain the results. Additionally, more effort has been focused on obtaining accurate ice shapes using a 3D scanning system. Results of 3D scans are given.

Generation of Validation Data for an Electrothermal Ice Protection System

Richard Moser, Bernhard Reinholz, Wolfgang Breitfuß, Stefan Diebald, Philipp Kollmann, Sebastian Humpel, Reinhard Puffing, David Kozomara, Simon Schweighart, Wolfgang Hassler, Thomas Neubauer and Andreas Tramposch

AIAA AVIATION FORUM 2022, DOI: https://doi.org/10.2514/6.2022-3457

Abstract

This paper provides information on the generation of validation data for electrothermal ice protection system numerical tools, based on testing on a 2D wing section at the RTA test facility in Vienna. Updates to the RTA calibration capability are provided, including for the Freezing Rain, MVD > 40 microns regime. Latest developments in ice shape scanning and post-processing are shown, including for runback ice generated from heated cases. Some preliminary comparisons to the measured data are provided using different simulation tools, including unheated ice shapes.

Experimental Investigation on the Effects of Icing on Multicopter UAS Operation

David Kozomara, Thomas Neubauer, Reinhard Puffing, Ingeborg Bednar and Wolfgang Breitfuss

AIAA AVIATION FORUM 2021, DOI: https://doi.org/10.2514/6.2021-2676

Abstract

The implications of icing for the operation of multicopter unmanned aerial systems (UAS) have not been thoroughly investigated yet. Due to the geometry and flight envelope of multicopters, existing knowledge in the field of aircraft icing can only be applied in a limited manner. More research is required to better understand the influence of icing on the flight characteristics, on-board systems, and sensors of multicopters. Studies performed on single UAS propellers show that icing can lead to critical flight conditions in a very short period of less than 60 seconds. Icing of the propeller blades reduces the aerodynamic performance while increasing the required power input at constant rotational speed. This paper features a more top-level approach and investigates the effects of icing on the operation of a multicopter with 25 kg maximum take-off weight. Therefore, experimental icing tests were conducted at the Rail Tec Arsenal Climatic Wind Tunnel in Vienna, Austria. The multicopter was mounted on a testbed and operated in defined icing conditions according to Appendix C and Appendix O (freezing drizzle) conditions. The rotational speed of the propellers was maintained until a certain power limit, or the predefined icing time was reached. The final ice accretion was documented by means of 3D scanning and evaluated. Moreover, a surface roughness analysis of the propeller blade ice accretion was performed.

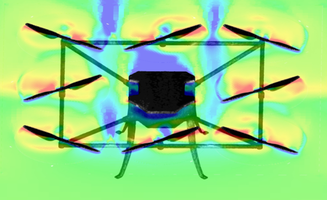

Determination of Droplet Impingement on an Octocopter at different Flight and Icing Conditions with CFD Methods

Andreas Tramposch, Michael Thomann and David Kozomara

AIAA AVIATION FORUM 2021, DOI: https://doi.org/10.2514/6.2021-2501

Abstract

A simple and efficient CFD workflow was developed to identify critical areas on small multicopters in regard of ice accretion when flying in icing conditions. Using a transient rotor stator model for rotor blade simulation inside a stationary domain containing the multicopter airframe, a transient Euler-Lagrangian multiphase flow simulation was used to calculate water droplet trajectories and impingement for various icing and flight conditions. For an Appendix O freezing drizzle icing case the numerical results from an octocopter cruise flight were validated with measurement data gained from an experimental investigation performed in the Rail Tec Arsenal Icing Wind Tunnel in Vienna, Austria for same icing and flight conditions. Thereafter, total and local droplet impingement rates on the octocopter obtained from CFD simulations were compared with results gained from 3D scans of the octocopter with accrued ice after the experimental icing process.

Assessment of Ice Shape Roughness via Automatic Spacing of Codebook Vectors in a Two-Dimensional Self-Organizing Map

Thomas Neubauer and Reinhard Puffing

AIAA AVIATION FORUM 2020, DOI: https://doi.org/10.2514/6.2020-2806

Abstract

Characterization and assessment of ice shape roughness can be done by evaluating the point cloud from a three-dimensional scan of the iced surface. One way of evaluating this point cloud is the application of the neural network technique Self-Organizing Maps (SOM), which was already successfully applied in previous examination and studies of ice shape roughness. This algorithm is based on codebook vectors, which position themselves in local clumps of multidimensional and noisy data. The connection of those codebook vectors represents the mean shape or manifold of the investigated rough object. The magnitude of scattering of the data points about this manifold can then be interpreted as the roughness by applying statistical evaluations. The amount of codebook vectors needed is usually an input parameter for the algorithm. The manual process of determining different regions in the shape and determination of their optimal number of codebook vectors is a time consuming and iterative process. However, a certain statistical requirement exists on how sparse or dense the codebook vectors shall be positioned. In this study, this requirement is used to automate the whole process from point cloud input to calculation of the roughness parameters for each codebook vector region. This algorithm is exemplarily applied to a NACA 0012 wing, exposed to appendix C icing conditions in the icing wind tunnel of Rail Tec Arsenal in Vienna, Austria.

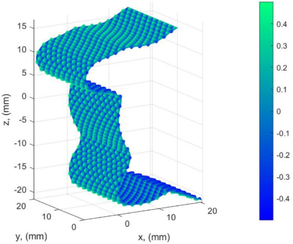

Ice Shape Roughness Assessment Based on a Three-Dimensional Self-Organizing Map Approach

Thomas Neubauer, Wolfgang Hassler and Reinhard Puffing

AIAA AVIATION FORUM 2020, DOI: https://doi.org/10.2514/6.2020-2805

Abstract

One approach of performing ice roughness analysis is the evaluation of three-dimensional scanned point clouds of the iced surface. The point cloud data can then be evaluated via the neural network technique Self-Organizing Maps (SOM). A two-dimensional version of this machine learning algorithm has already been successfully applied in previous studies. However, an extension to three dimensions is highly desirable, as it enables the evaluation of ice roughness on arbitrary surfaces and shapes. Nevertheless, the implementation in three dimensions holds some difficulties, as curvature-induced roughness artefacts occur during evaluation. In this paper, the extension of the SOM algorithm from two to three dimensions is presented. Furthermore, a method for the mitigation of curvature induced roughness artefacts is introduced. This curvature correction is based on a local surface and curvature approximation and significantly reduces the curvature-induced errors. Two test cases for validation of the curvature-corrected three-dimensional SOM method are presented. The first test case is an artificially created point cloud with known and assigned roughness. The second test case is a 3D scanned point cloud of an NACA0012 wing, exposed to SLD icing conditions in the icing wind tunnel of Rail Tec Arsenal in Vienna, Austria.

Validation of Ice Roughness Analysis Based on 3D-Scanning and Self-Organizing Maps

Thomas Neubauer, David Kozomara, Reinhard Puffing and Wolfgang Hassler

SAE 2019 International Conference on Icing of Aircraft, Engines, and Structures, DOI: https://doi.org/10.4271/2019-01-1992

Abstract

3D-scanning is an established method for the documentation of wing ice accretion. The generated 3D-data can be used to determine specific parameters of interest, like the local ice-thickness, or the surface ice roughness. The surface roughness has significant impact on the heat transfer, and therefore on the icing process itself. Insights into the effects of surface roughness on the ice accretion and the correlated aerodynamical effects contribute to the improvement of icing codes. In this paper, the surface roughness of various test specimens is determined by performing a self-organizing maps (SOM) approach for roughness point cloud analysis on data generated with a 3D-scanner. A validation of the SOM method is achieved by means of focus variation microscopy and a mathematical proof of the utilized SOM algorithm. Different scanning systems from several manufacturers are used to determine the surface of different sandpapers. This investigation shows the limits and capabilities of state-of-the-art 3D-scanning systems in the field of surface roughness. Furthermore, the roughness model is calibrated to absolute surface parameters, such as the mean arithmetic roughness Ra or the root mean squared roughness Rq.

Aerodynamic Assessment of Complex 3D Ice Shape Replications

Reinhard Puffing, Wolfgang Hassler, Thomas Neubauer, David Kozomara and Hermann Ferschitz

SAE 2019 International Conference on Icing of Aircraft, Engines, and Structures, DOI: https://doi.org/10.4271/2019-01-1936

Abstract

This work introduces an approach allowing the detailed replication of ice shapes generated in icing wind tunnels, with a special focus on complex and strongly varying ice structures, e.g., ice feathers or residual ice stemming from incomplete removal of accreted ice by ice protection systems. 3D-scans are used as an input for the manufacturing process of the ice shape replica. The manufacturing approach itself is based on additive techniques using semi-flexible materials. In contrast to existing replication techniques, this approach allows also clean areas between ice-covered surface locations. In the present paper, a quality assessment based on the comparison of the lift coefficients of real and corresponding artificial ice shapes is presented.

Ice Shape Mapping by Means of 4D-Scans

Reinhard Pufffing, Wolfgang Hassler, Andreas Tramposch and Marian Peicar

SAE 2015 International Conference on Icing of Aircraft, Engines, and Structures, DOI: https://doi.org/10.4271/2015-01-2151

Abstract

When studying ice accretion processes experimentally it is desirable to document the generated ice shapes as accurately as possible. The obtained set of data can then be used for aerodynamic studies, the improvement of icing test facilities, the development of design criteria, the validation of ice accretion simulation tools as well as other applications. In the past, various ice shape documentation methods have been established including photography, cross-sectional tracing, molding and casting as well as 3D-scanning. This work introduces a new ice shape documentation technique based on active 3D-scanning in combination with fluorescent dyes and an optimized set of optical filters. The new approach allows recording the time-resolved three dimensional growth of an arbitrary ice shape. Based on this concept a so-called 4D-scanning system is developed, which allows a detailed evaluation of icing experiments and hence a better understanding of the ice accretion process itself. The scanning system has been successfully implemented and tested in two icing wind tunnels of completely different size, namely FH JOANNEUM's small scaled icing wind tunnel and Rail Tec Arsenal's large icing wind tunnel.

Computational and Experimental Investigation of Ice Particle Accretion in a Generic Pack Discharge Duct

Andreas Tramposch, Wolfgang Hassler and Reinhard Puffing

SAE 2015 International Conference on Icing of Aircraft, Engines, and Structures, DOI: https://doi.org/10.4271/2015-01-2082

Abstract

Certain operating modes of the Environmental Control System (ECS) of passenger aircraft are accompanied with significant ice particle accretion in a number of pivotal parts of the system. Icing

conditions particularly prevail downstream of the air conditioning packs and, as a consequence, ice particle accretion takes place in the Pack Discharge Duct (PDD) and in the mixing manifold. For

a better understanding of these icing processes, numerical simulations using a multiphase model based on a coupled Eulerian-Lagrangian transport model in a generic PDD were performed. The

obstruction of the PDD due to ice growth and the resulting change of the flow geometry were treated by deforming the computational mesh during the CFD simulations. In addition to the numerical

investigations, a generic and transparent PDD was studied experimentally under several operating conditions in FH JOANNEUM's icing wind tunnel.

Thermal Ice Protection of Restraining Grids in the Environmental Control System of Passenger Aircraft

Wolfgang Hassler, Reinhard Puffing and Andreas Tramposch

SAE 2015 International Conference on Icing of Aircraft, Engines, and Structures, DOI: https://doi.org/10.4271/2015-01-2095

Abstract

This paper deals with thermal ice protection of electrically heated restraining grids designed for applications in the environmental control system (ECS) of passenger aircraft. The restraining grids described in the paper consist of strung, electrically insulated wire and are - in certain operation modes of the ECS - exposed to an airstream containing supercooled water droplets and/or ice particles. Heat is generated in the wire by an electric current, and the temperature of the wire is controlled with the aid of an electronic control system. A substantial question for laying out the controller and for operating the grids is the following: What minimum heating power is required to prevent ice accretion on the surface of the wire, i.e., what is the least heating power that is necessary to keep a grid being exposed to specific icing conditions devoid of ice? This problem is studied for a simple model system first and is then examined for restraining grids. The methods utilized for these investigations include icing wind tunnel experiments, numerical simulations involving FH JOANNEUM's icing code ICEAC2D v2 as well as analytical calculations.